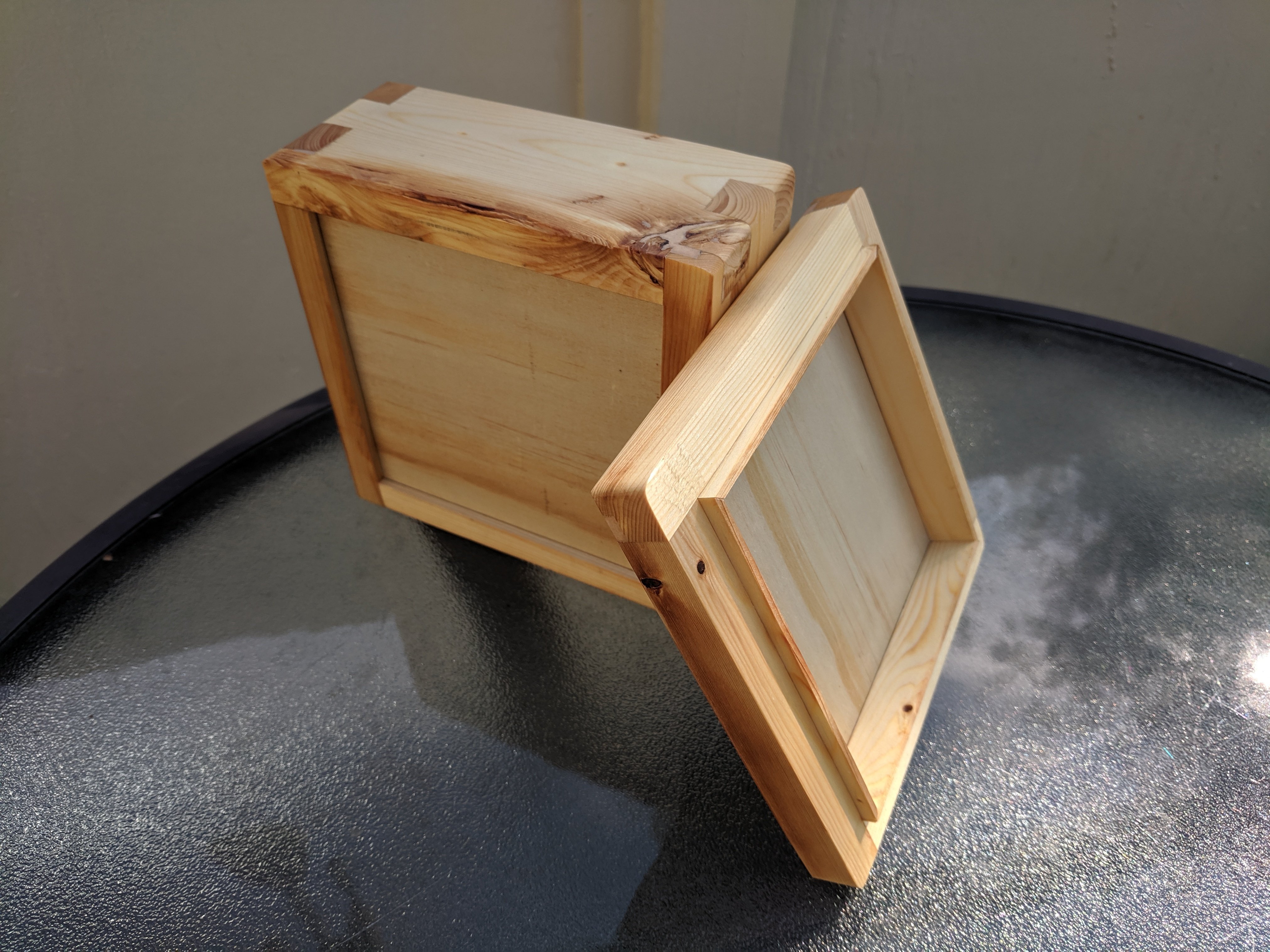

I like the idea of using it as a small decorative shelf, thanks.

pageflight

And there's a whole community for them! Not sure how to link to it though.

Back to building with stone, metal, and wood.

Nice! Direct link. The Atlantic's crossword was outpacing my mini-crossword abilities/patience.

I wish them well, I would like to see more unions in tech.

Knock knock. Who's there? Boo! ...

Maybe I'll give them a go for my next automation! Thanks for the recommendation.

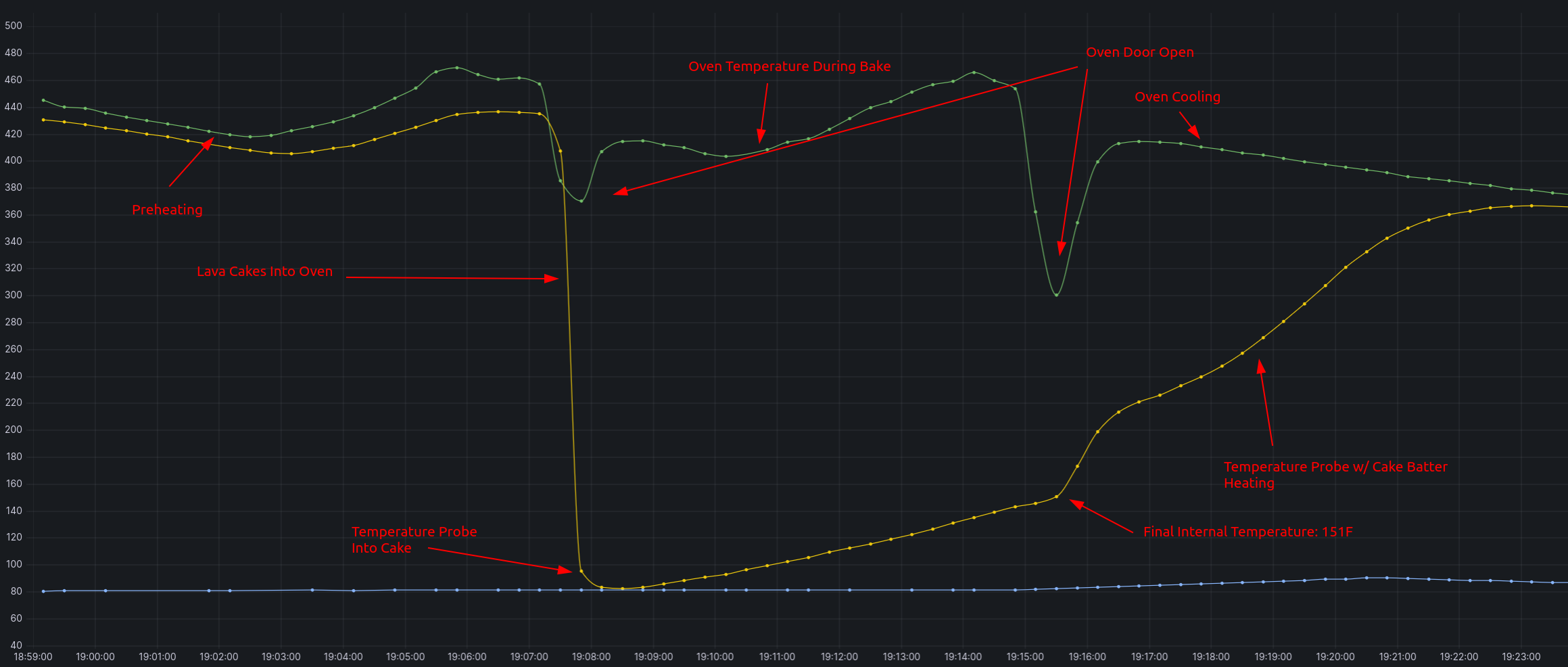

I do have a hub — using HomeAssistant with AppDaemon.

Yes -- should've described that aspect. The shape of the entryway means that none of the existing switches has a good view of all the area I'd like a motion sensor to trigger on. Otherwise that would be the way to go!

According to the myth, Zeus saw and fell in love with a beautiful mortal youth by the name Ganymede. Ganymede was abducted by Zeus from Mount Ida near Troy in Phrygia. Ganymede had been tending sheep, a rustic or humble pursuit characteristic of a hero's boyhood before his privileged status is revealed, when an eagle transported the youth to Mount Olympus. The bird is sometimes described as being under the command of Zeus and sometimes as being Zeus himself.

I have Hi2 heat pumps in a 100yo house with recently improved insulation, and it was just fine last year in -15F weather. No gas backup.

One family member has been talking to installers and they keep telling her that heat pumps can't work reliably, it's extremely frustrating.

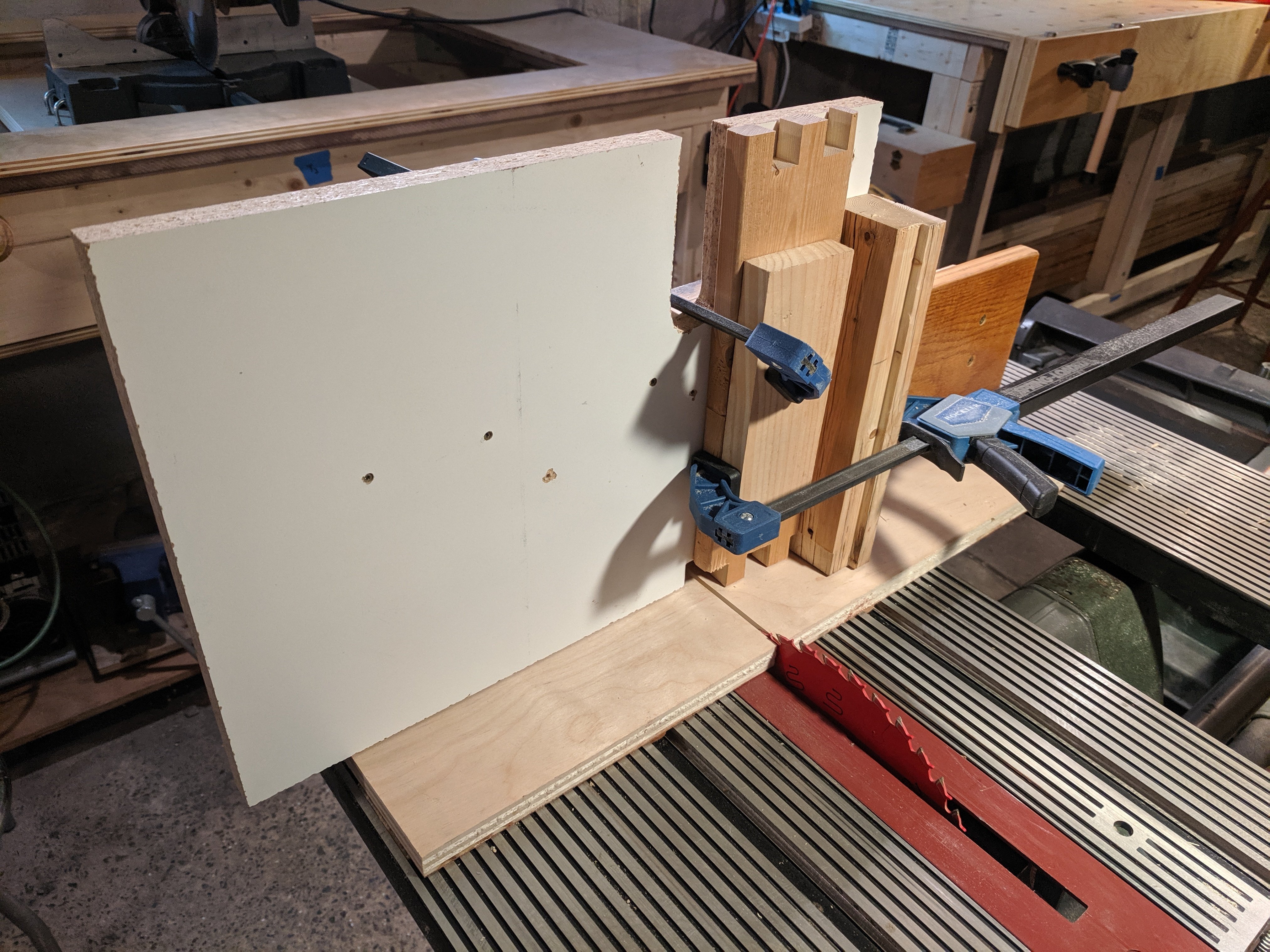

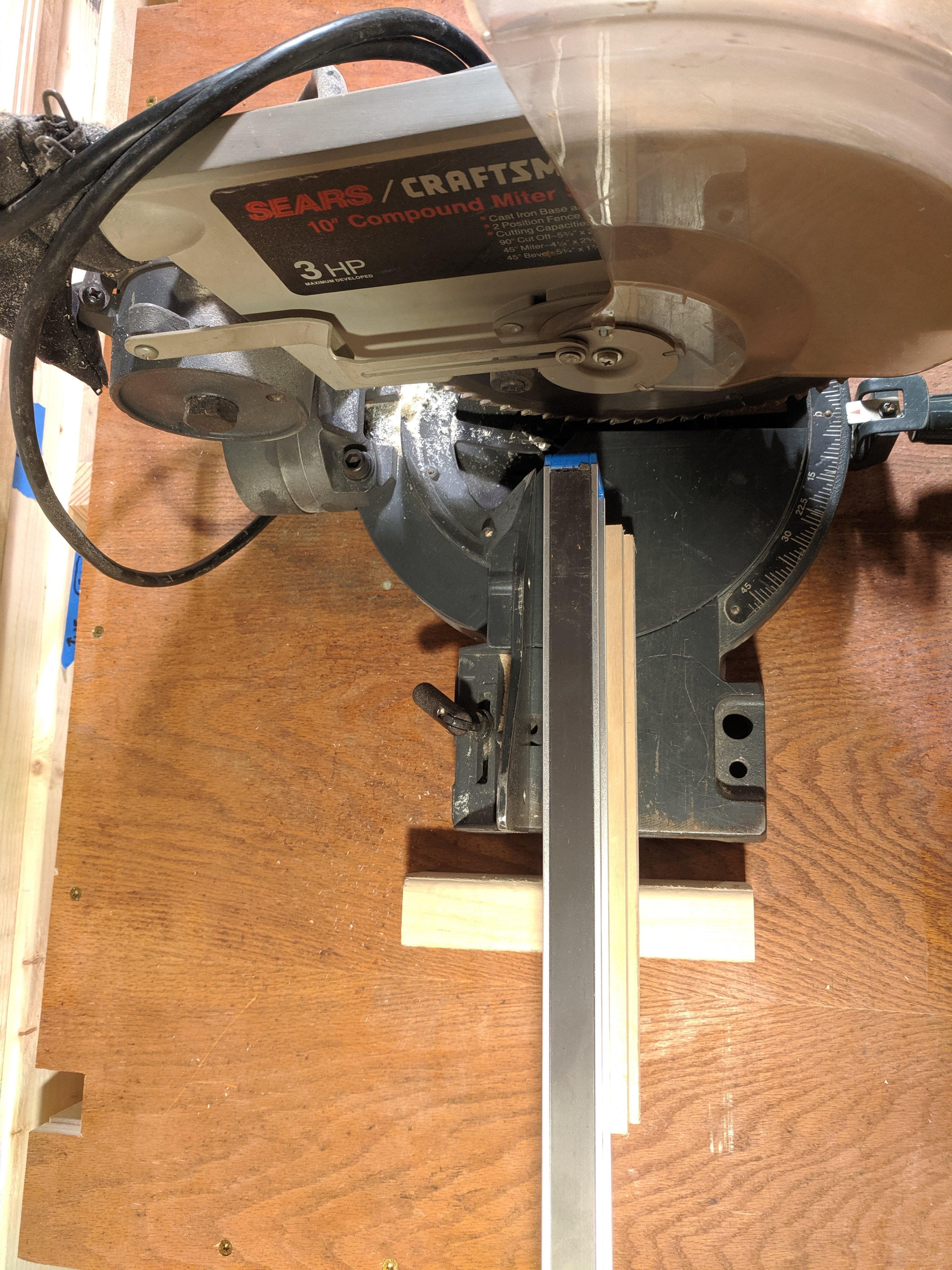

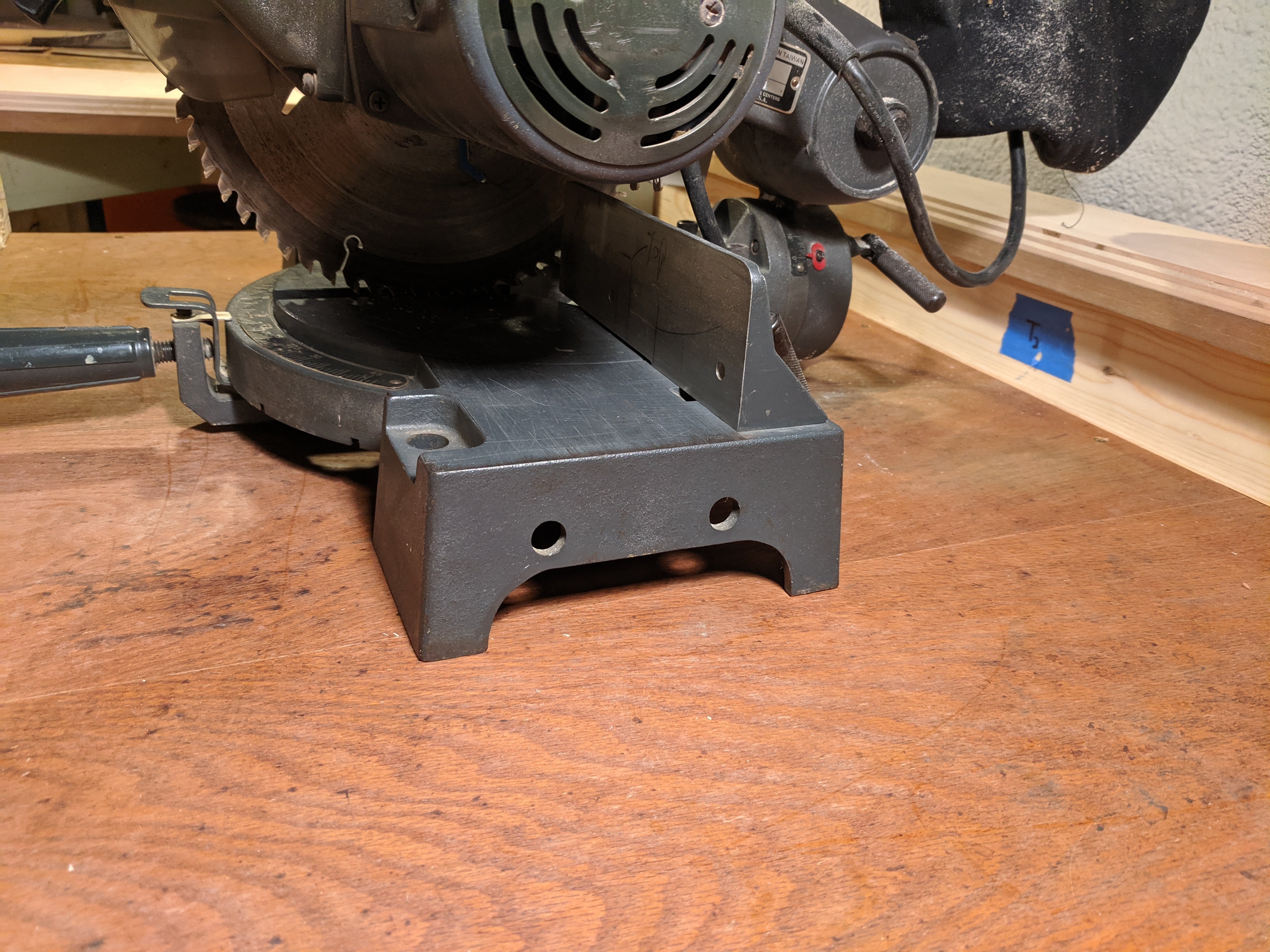

I just made a table saw box joint jig, I like the idea of using that to redo the joints on this.

And thanks for the word of caution about chipping on very hard wood, maybe I can test on a small area.

If so else fails, some nice scrap wood for making splines.