Are those gears meshing properly when you spin the handle? It sounds like they're skipping, and just from the brief part in the video it looks like the blade isn't raising steadily.

I don't think they are skipping. It gets smoother when I have the saw on it's side.

Yeah that saw has been abused.

No, it should run up and down smoothly.

First thing I would do is remove the bevel gear on the crank wheel side and turn the jack screw side by hand, testing to make sure the saw assembly runs up and down smoothly.

Mostly though I suspect the bevel gears. What I'm seeing looks like they're meshed incorrectly/too tightly. Try any adjustment to move them relative to each other, ie back them away from each other slightly. I can't tell if the shaft bosses have any adjustment or ability to loosen them; if they do I would loosen them slightly, turn the handle to see if the gears find somewhere they like, and then tighten it back down. Looks like it's a simple cast assembly though.

You may be right about the tightness. I noticed that the spinning gets smoother when the saw is on it's side as seen here in the second video I made. https://youtu.be/MdXE7IPnA6s?si=AteFwlZ1x2kFfOVt

Yeah that's almost certainly the gear mesh.

There's a boss that supports the jack screw near the gear end, is there any way to loosen and adjust it?

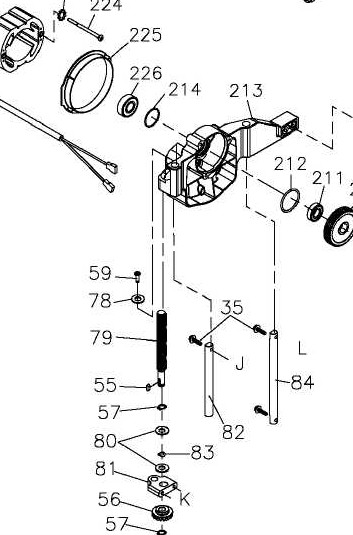

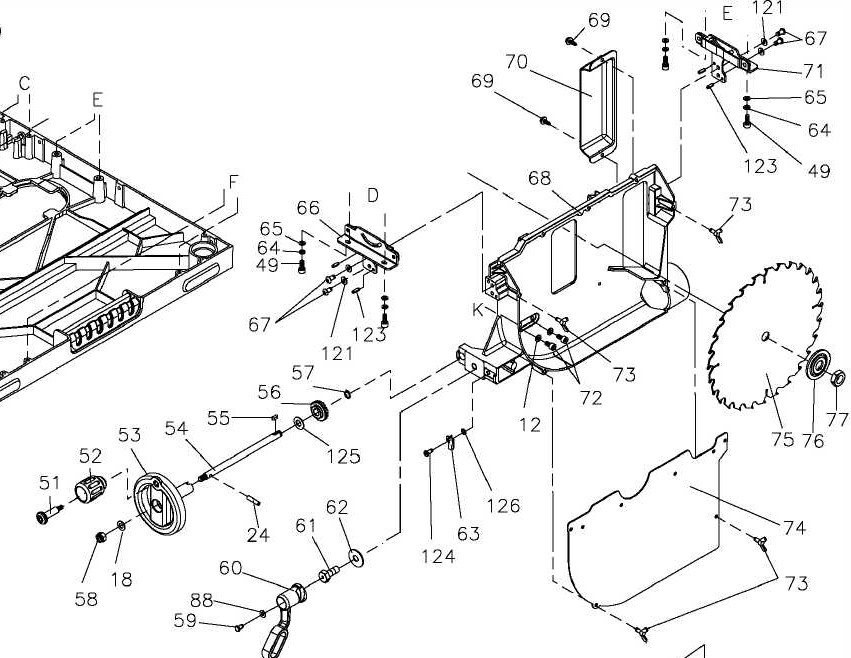

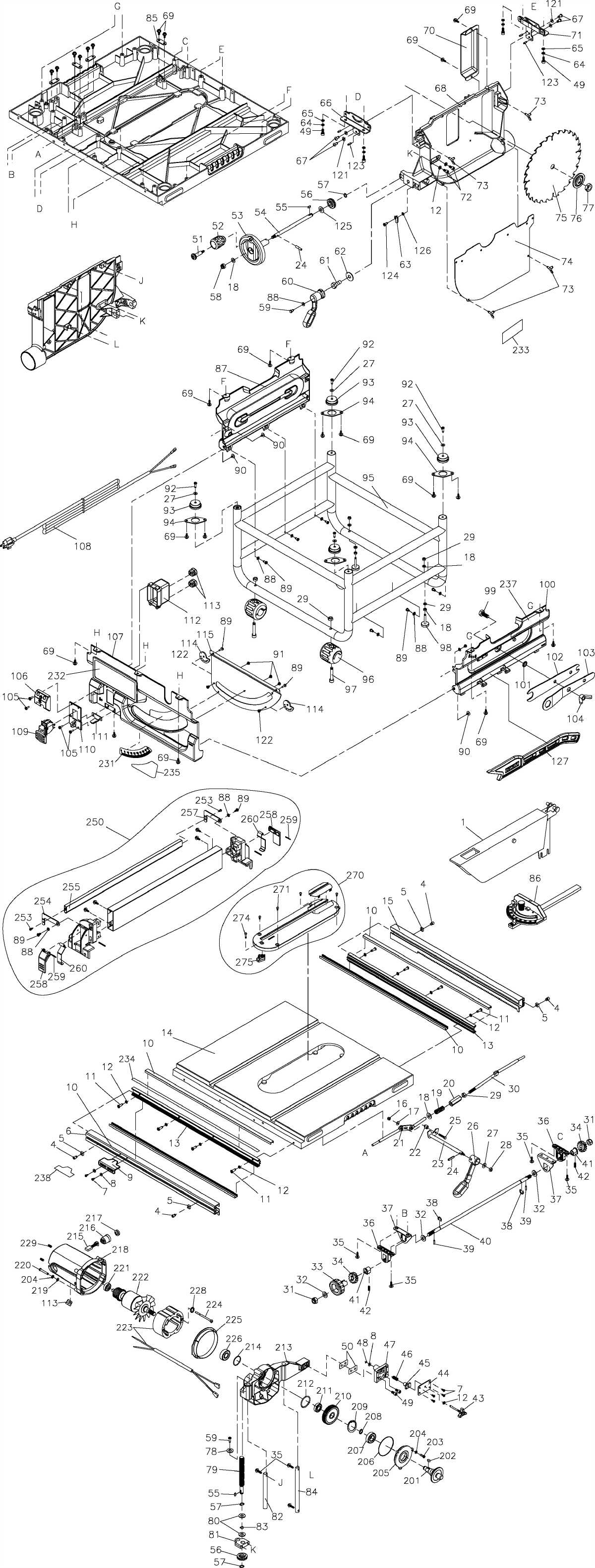

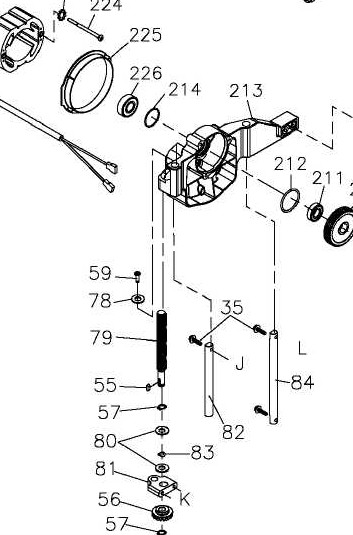

I'm attempting to learn what a shaft boss is so I can find it. Is there a part number on this exploded diagram that you can refer to?

It may be in the 30s or 50s (if that helps you find it)

A shaft boss is the bracket that holds the shaft in place; the hole that the shaft passes through. Like look at #81 in the top diagram there.

yeah you might want to slightly loosen that amd see if it'll shift a bit to let the gears mesh more comfy.

Well, the screws were definitely over torqued, but it didn't fix the issue. I tried multiple methods to get one of the screws out but had to use a grinder and a flathead screwdriver to get it out.

I think I may have an Idea what is causing the issue after looking at the gears after your advice.

Since the clanky movement really only happens in one direction when the saw is on its side I figured it had something to do with the direction of the pressure being applied by the screw mechanism.

When I put the table saw completely upside down and then tried to move the blade up and down it was very smooth.

This led me to think that there might be some movement in the gears based on the pressure that's being applied. Watch this video to see what I'm talking about and you'll see a gap that closes when I go in one direction and opens back up in the other.

You can see the movement of the gear at about the 1:04 mark in the video.

https://youtu.be/4J7jqrm9Sn4?si=UAGNhSC3HjRo7LS8

Any advice?

I'm looking at this part of the diagram

I'm noticing part 83 (Washer 5140032-75)

That washer appears to be bent on purpose on the linked website for replacement parts and I'm guessing that it would keep the tension on the threaded dowel consistent. I think mine is missing or it was flattened out when someone torqued the mechanism.

Upon further research that is a bowed washer, spring washer, curved washer or wave washer. Their purpose is to retain tension and it's likely the solution to my gears binding. More can be explained in this video: https://youtu.be/sG1gSQGZQl8?si=nQhzR2a8TZUwJ5rY

That's another guess.

Would like to get some guidance here.

I'm not entirely sure here, I have a new DW7485 so i'm not sure if the mechanisms are entirely identical. It does seem that the jack screw is translating along its length and it shouldn't. Not entirely sure why it is free to move like that, a missing or damaged spring washer might, like having looked at your video it does appear like there should be more things taking up space in that area.

I am reluctantly ordering a single wave washer here for $9.76 if you include shipping:

5140032-75 Washer, Curved, 10.1 X 17Mm - Dewalt®

I checked all of my local hardware stores. I think Lowes usually has these, but they said their small parts vendor hasn't come to restock anything in a long time and they weren't sure when they would be coming back. All other hardware stores in my area didn't have them or staff wasn't very helpful.

I will keep everyone updated. I hope this is the last part that I need to order online. I'll try to do a summary video when I'm done because I haven't found many that really get into this level of detail on repairing this specific issue online. I'm just glad I'm keeping this thing out of the dump and I hope to start using it soon so I can start to build and repair some stuff around the house. Super excited about building a French Cleat system in my shed.

That do it?

Still waiting on the part. USPS is late with the shipment.

I won't let you down. I'll keep ya posted. Thanks again for all the help!

Got the part in but my wife went into labor. We had a 8 lb 7 oz baby!

Obviously this is going to delay the progress of this saw project.

I did want to mention that the bent washer isn't very "bent". I'm going to figure out how to provide measurements once I can get to focus on this again.

I promise I'll get y'all updates at some point.

Congratulations! now get out of here and you go be an awesome new dad. That table saw will wait.

Still waiting on the part.

USPS says it should be here tomorrow (05/10/2024).

I'm looking forward to using this thing for so many projects.

A 'boss' is a round protrusion in the casting, typically to support a shaft or provide a thicker cross section for threads.

Thank you!! I always appreciate learning something new.

As others have said it should be quiet and smooth.

Woodworking

A handmade home for woodworkers and admirers of woodworkers. Our community icon is submitted by @[email protected] whose father was inspired to start woodworking by Norm and the New Yankee Workshop.