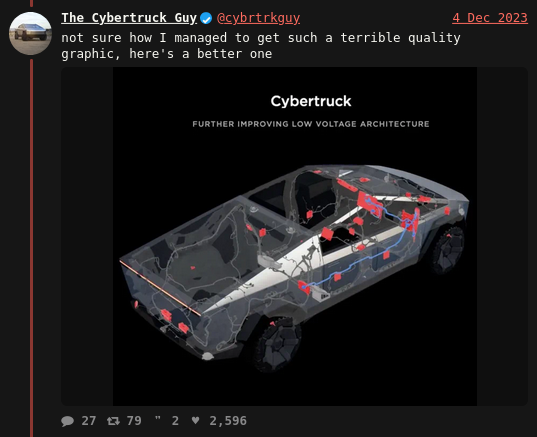

I work in the automotive industry (specifically on steering ECUs and domain controllers). Switching to ethernet doesn't significantly reduce the amount of copper in the vehicle. In addition, whoever wrote this post has no idea what they're talking about.

The other standard automotive networks (CAN, LIN, Flexray, etc) are daisy-chained. So your steering, brakes, drive train and other core ECUs are all on the same two wires. Ethernet, on the other hand, doesn't actually support that--every ECU needs to run to an active switch in order to communicate on the network. OOP has it completely backwards. Ethernet is beneficial for offering higher bandwidth than the other technologies, but it doesn't significantly save on copper (it may even require more).

Most vehicles have more than one network, to isolate the core ECUs for important functions (e.g., steering, braking, throttle, etc) from the less important ones (doors, wipers, media, etc). In addition, any vehicle made in the last 5 years or so would be likely to have a redundant network for the core network, especially if it supports any level of automated driving functions (lane keeping, auto parking, adaptive cruise, etc).

The only way to save 77% on wiring would be to either put everything on one network, or not have redundant networks, or both. Which, in an autonomous vehicle, would violate a plethora of safety standards. I can't say what the cyber truck has in it, so we'll assume OOP is full of shit.

FYI, nobody with half a brain in the automotive industry will work for Tesla. I got to talk with a couple of former engineers, they indicated they were forced to compromise their integrity and left, and refused to elaborate on it. For what it's worth.