this post was submitted on 18 Mar 2025

80 points (96.5% liked)

Cyberstuck

840 readers

477 users here now

A place to post your Cybertruck fails! We're here to make fun of this hunk of shit and throw as much shade as we can to that garbage bag of a human elon.

No doxxing No slurs No racism And no fucking nazis!

founded 2 months ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

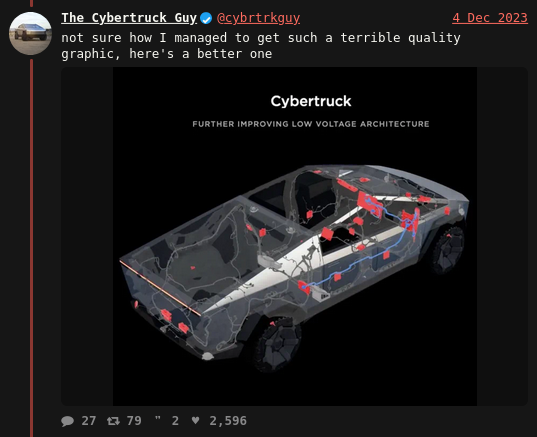

I work in the automotive industry (specifically on steering ECUs and domain controllers). Switching to ethernet doesn't significantly reduce the amount of copper in the vehicle. In addition, whoever wrote this post has no idea what they're talking about.

The other standard automotive networks (CAN, LIN, Flexray, etc) are daisy-chained. So your steering, brakes, drive train and other core ECUs are all on the same two wires. Ethernet, on the other hand, doesn't actually support that--every ECU needs to run to an active switch in order to communicate on the network. OOP has it completely backwards. Ethernet is beneficial for offering higher bandwidth than the other technologies, but it doesn't significantly save on copper (it may even require more).

Most vehicles have more than one network, to isolate the core ECUs for important functions (e.g., steering, braking, throttle, etc) from the less important ones (doors, wipers, media, etc). In addition, any vehicle made in the last 5 years or so would be likely to have a redundant network for the core network, especially if it supports any level of automated driving functions (lane keeping, auto parking, adaptive cruise, etc).

The only way to save 77% on wiring would be to either put everything on one network, or not have redundant networks, or both. Which, in an autonomous vehicle, would violate a plethora of safety standards. I can't say what the cyber truck has in it, so we'll assume OOP is full of shit.

FYI, nobody with half a brain in the automotive industry will work for Tesla. I got to talk with a couple of former engineers, they indicated they were forced to compromise their integrity and left, and refused to elaborate on it. For what it's worth.

The OP over simplified and didn't understand.

This Autoevolution Article explains it better. It is not Ethernet, it is power over canbus with distributed control nodes. So I totally buy it using less copper and being a smarter way to do electric car wiring.

Ah, that does make more sense. Having controllers focused on the physical location of components would definitely save on wiring compared to routing them by function. And the connector thing is clever, though I'd be curious to read up on their power-and-data-on-two-wires thing.

One thing in this article to note though--Tesla isn't the first to utilize steer-by-wire. That's literally been around since 2013 (Infiniti was the first, I believe). Most vehicles that used it early on had a physical column that could be engaged as a backup. You know, for safety. The cyber truck is the first fully electric vehicle to not have a physical column, but every other major OEM has them in the pipeline for the next few years. And plenty already have them, but with a physical column as a backup.

In addition, it's worth noting that ethernet does not give lower latency, it offers higher bandwidth. There are plenty of SbW systems using CAN, the latency is quite good as long as you're not overcrowding your bandwidth limits.

So you can hack teslas from their door handles? Sounds like security and maintenance nightmare

The only way you could hack a Tesla via the door handle is if you were using a hatchet.