this post was submitted on 10 Mar 2025

21 points (100.0% liked)

Electronics

2291 readers

25 users here now

Projects, pictures, industry discussions and news about electronic engineering & component-level electronic circuits.

Rules

1: Be nice.

2: Be on-topic (eg: Electronic, not electrical).

3: No commercial stuff, buying, selling or valuations.

4: No circuit design or repair, tools or component questions.

5: No excessively promoting your own sites, social media, videos etc.

Ask questions in https://discuss.tchncs.de/c/askelectronics

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

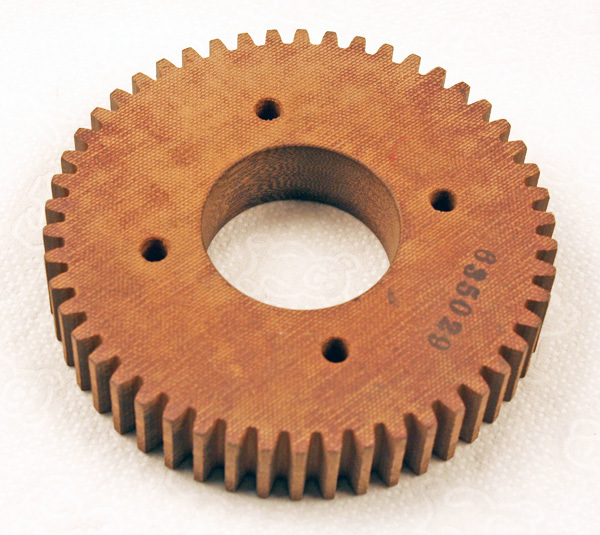

Woah those are some cool properties, I wonder how hard these gears would be to manufacture at home? I'm looking at implementing my own custom gear reductions in servos but I don't think my 3d prints will mesh well enough or withstand long usage

There are some youtube videos of people machining them (sadly my browser does not support smell). Looks like you treat it like any other solid material: hobb or mill the teeth. This is much more expensive than 3d printing.

You might be surprised by your 3d printed gears. If you keep the detail size large they work really well, but backlash is definitely an issue.