view the rest of the comments

the_dunk_tank

It's the dunk tank.

This is where you come to post big-brained hot takes by chuds, libs, or even fellow leftists, and tear them to itty-bitty pieces with precision dunkstrikes.

Rule 1: All posts must include links to the subject matter, and no identifying information should be redacted.

Rule 2: If your source is a reactionary website, please use archive.is instead of linking directly.

Rule 3: No sectarianism.

Rule 4: TERF/SWERFs Not Welcome

Rule 5: No ableism of any kind (that includes stuff like libt*rd)

Rule 6: Do not post fellow hexbears.

Rule 7: Do not individually target other instances' admins or moderators.

Rule 8: The subject of a post cannot be low hanging fruit, that is comments/posts made by a private person that have low amount of upvotes/likes/views. Comments/Posts made on other instances that are accessible from hexbear are an exception to this. Posts that do not meet this requirement can be posted to !shitreactionariessay@lemmygrad.ml

Rule 9: if you post ironic rage bait im going to make a personal visit to your house to make sure you never make this mistake again

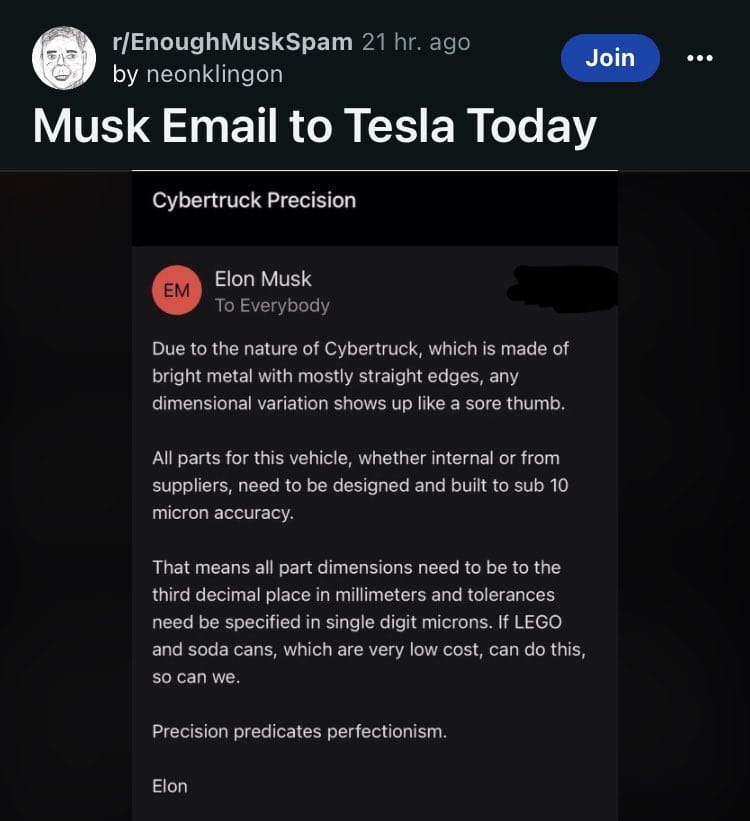

Depends on what it is. Some things like ball bearings need to be precise in order to work efficiently, but car body panels definitely do not need to be that precise. Pretty much nothing on a car needs to be within 10 microns.

You also have fun effects due to temperature, humidity, vibrations, heat radiation, etc. This means that large sheets produced in those precisions will still bend and all that, making the smoothness a bit absurd.

That said I could imagine that he mistranslated something his usability haptic researchers did tell him, that hands can detect irregularities up to 9 microns. Those numbers are relevant for how smooth surfaces have to be that people regularly touch. Still even in that most generous case it is a bit absurd, especially when we see Tesla's shoddy current construction.

Machinist would probably be the people that make the actual parts. They're guided by technical drawings, that specify the range of precision or whatever, as well as just how the thing is supposed to be. I think technical engineers make the drawings? I had to make them for machine-class, it fucking sucked. You need to be so incredibly clear with your lines.

A lot of things need a high amount of precision - semiconductors for example. That also just makes them incredibly difficult to make, which increases costs across the board. It's also just a pain in the ass for a machinist - Why does the cupholder need to be precise to within the 1000th of an inch? No reason.

This whole thing is incredibly dumb.

Also less reliable, "back in the old days" mechanical products had pretty loose tolerances, and the entire design was based on tolerating the loose tolerances. That way shit never breaks when it bumps around and is used for years. "High precision" is both wasteful and unneccessary, since once one thing goes wrong it can fuck up like 5 more things instantly.