3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Honestly? This seems like a really bad use case for FDM (less familiar with resin). Clear filament is very deceptive and actually getting reasonably translucent prints out of them can be a hassle. CNC Kitchen did a video on this a few years back. Far from perfect but https://www.youtube.com/watch?v=9qb25Gi4Jv0. Of particular note is the cooling and support related hassle which is of particular interest if you are printing light bulbs.

I get you don't care if it is clear. But clear filament gets REAL cloudy REAL fast and that is a factor with lighting.

Also? You already keyed in that UV and exposure are hell. Also understand that even LED bulbs can get pretty hot. Not hot enough to melt the plastic (probably) but likely enough to cause further clouding and so forth.

People very much underestimate just what a torture test xmas lighting is and why so many are designed to be more or less consumable objects. You can stretch that out if you properly maintain them in the off months but you are still expecting them to run for 8-12 hours a night for a month (or more) straight during some REALLY harsh weather.

I would also make sure the prints are actually water tight. Because properly wired lights are fine if a diode shorts out. How much do you trust your wiring for something that lives on the exterior of your home in the rain and snow? Hell, I barely even trust commercial xmas lights for that purpose.

I mean, you're probably not wrong, but what's the alternative? It's not as if I'm going to injection-mold them or machine them out of a solid block of plastic.

...

[sigh] Damn it, now you've got me researching DIY injection molding and rotomolding (once I finish writing this). Thanks a lot! 😠

Thanks for that video link; it was informative.

Regarding transparency/translucency: before even posting this thread, I had already done a quick-and-dirty test print of a C7 bulb cover with some Inland "natural" PLA I had lying around and "normal" settings -- not even really dialed in for my new printer at all, let alone customized for maximum transparency -- and it was fine (except for being slightly yellow). It's only a 2 perimeter thick shell, after all.

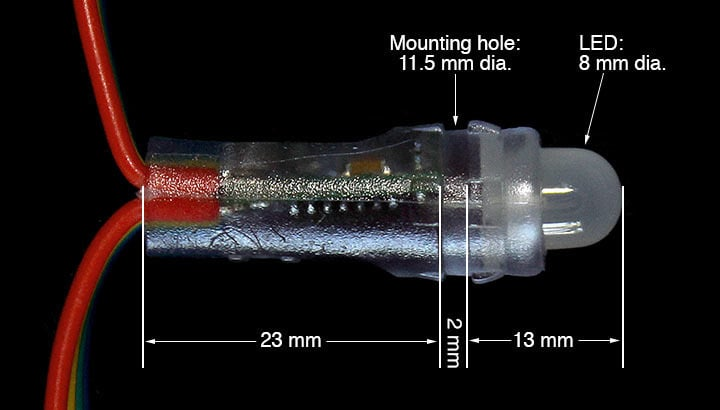

Heck, I might drop that down to one and use spiral vase mode, if I can figure out how to print the lugs that lock into the groove on the pixel in that mode, instead of a solid bottom layer.

Regarding lighting durability/water-tightness: the way these bullet pixels work is that the hole in the casing where the wires come in is completely filled with potting compound (at least 1/4" from the outside to anything conductive). Also, I'm doing all my wire splicing with marine grade solder seal heat shrink connectors. I'm pretty sure I could run the lights submerged and they'd be fine.

The things I'm printing are just decorative covers to diffuse the light into more interesting shapes. They have nothing to do with protecting the strand itself, and the worst that could happen if water gets in them is that they might get moldy or something.