3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

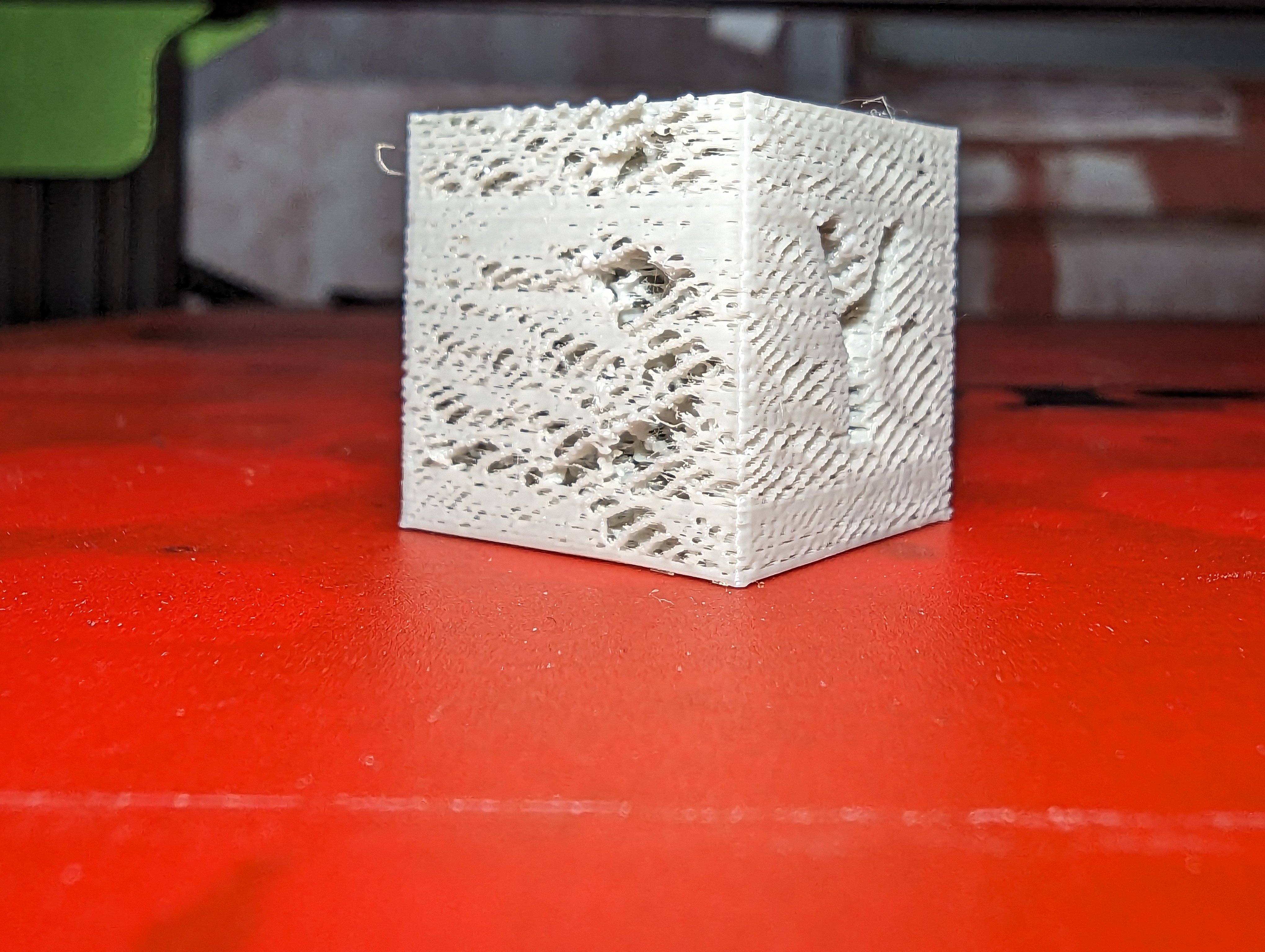

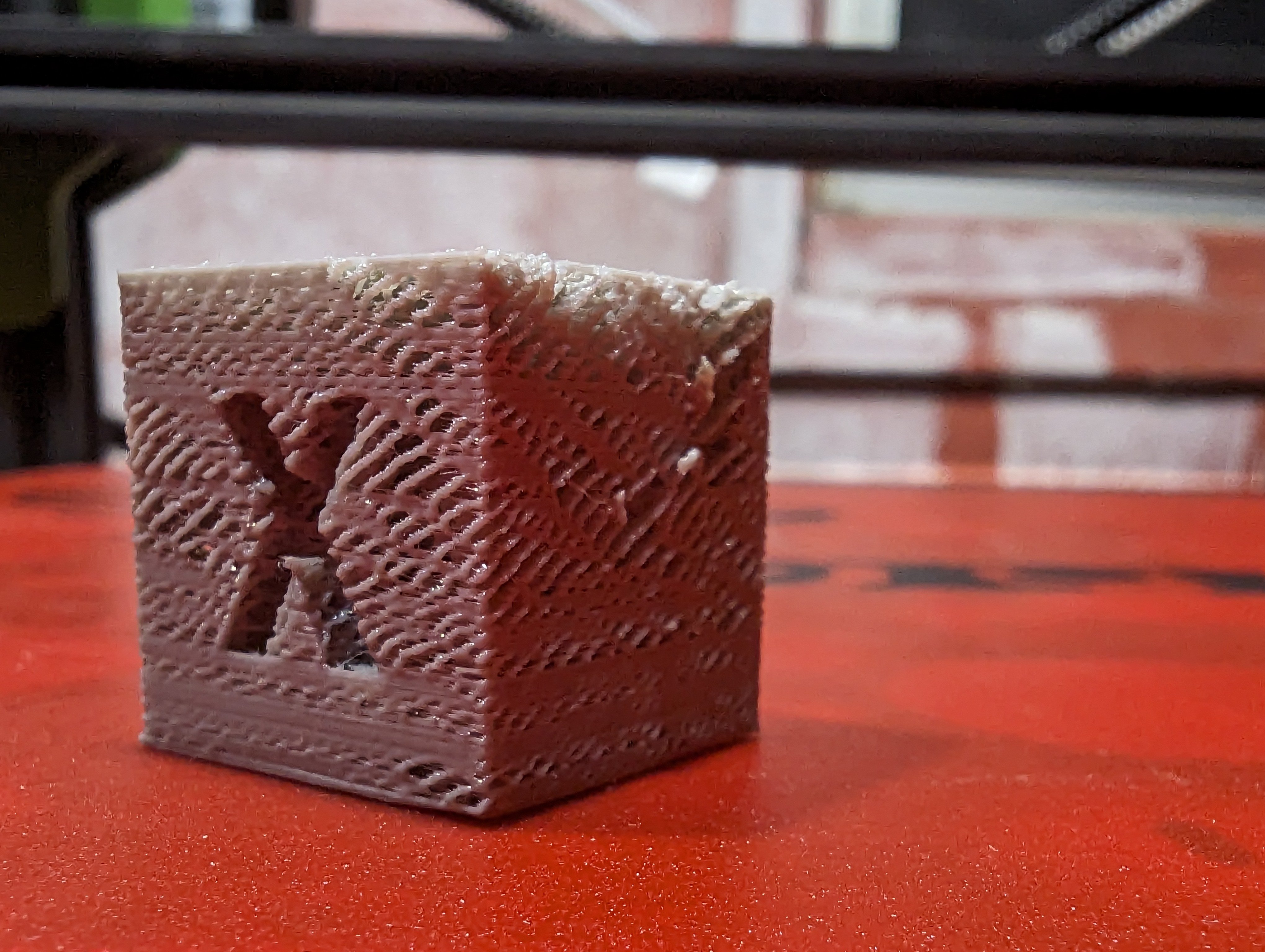

Underextrusion. You probably have burnt filament clogging your nozzle. Get your nozzle to 80C, then set it to 150C and start pulling the filament back out as the temperature climbs. It's called a cold pull and usually clears this sort of thing.

Set your initial builtplate temp to 70, and the builtplate temp to 55 for printing. At 70 the pla will hit glass transition, then when it cools to 55 the adherence will be very good.

If you want smooth walls, slow the speed to like 40mmps, and squish the layers down to 0.10 mm with a .4mm nozzle if you can.

Play with ironing for the top surface smoothing.

I don't recommend reducing your cooling much with pla. Maybe down to like 50% at the lowest.

Edit: your nozzle and later height should be fine, I glossed over that. Bring the nozzle down to 200 or so.

To add to this, I would highly recommend not worrying about using a .10mm layer height until you have reliable prints at .20mm height.

Trying to get finer detail is just compounding issues onto a print that looks to have quite a few things wrong.

I agree with you on underextruding. Easiest way to test would be for OP to measure 150mm of filament from the entrance of the extruder and mark it. Set nozzle temp to 215 or so, and manually extrude 100mm. Then re-measure to your mark and see how far off you are. If it's way off OP needs to calibrate his extruder motor steps.

Also as other people have said, might be worth trying a different filament, especially if that filament is really old.