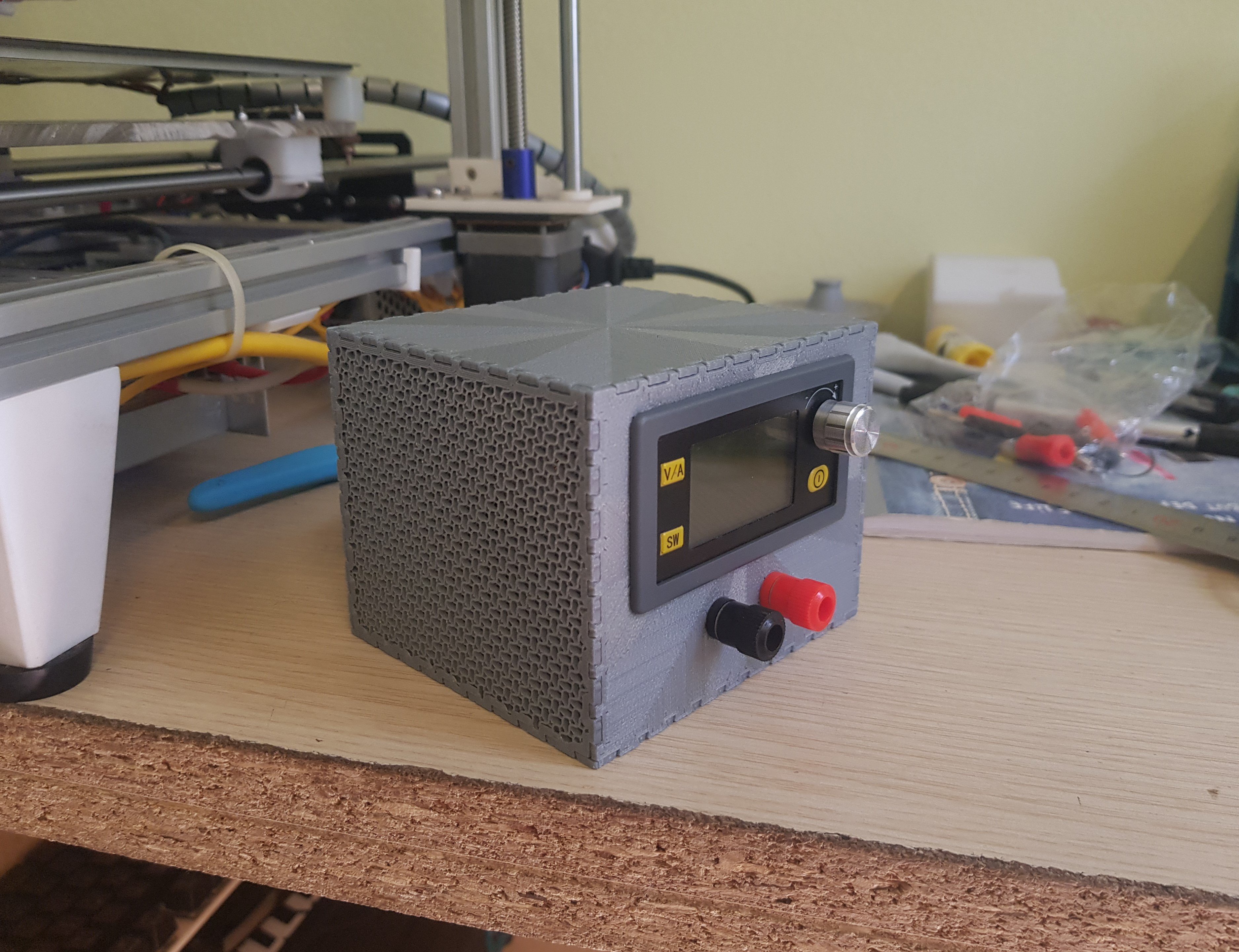

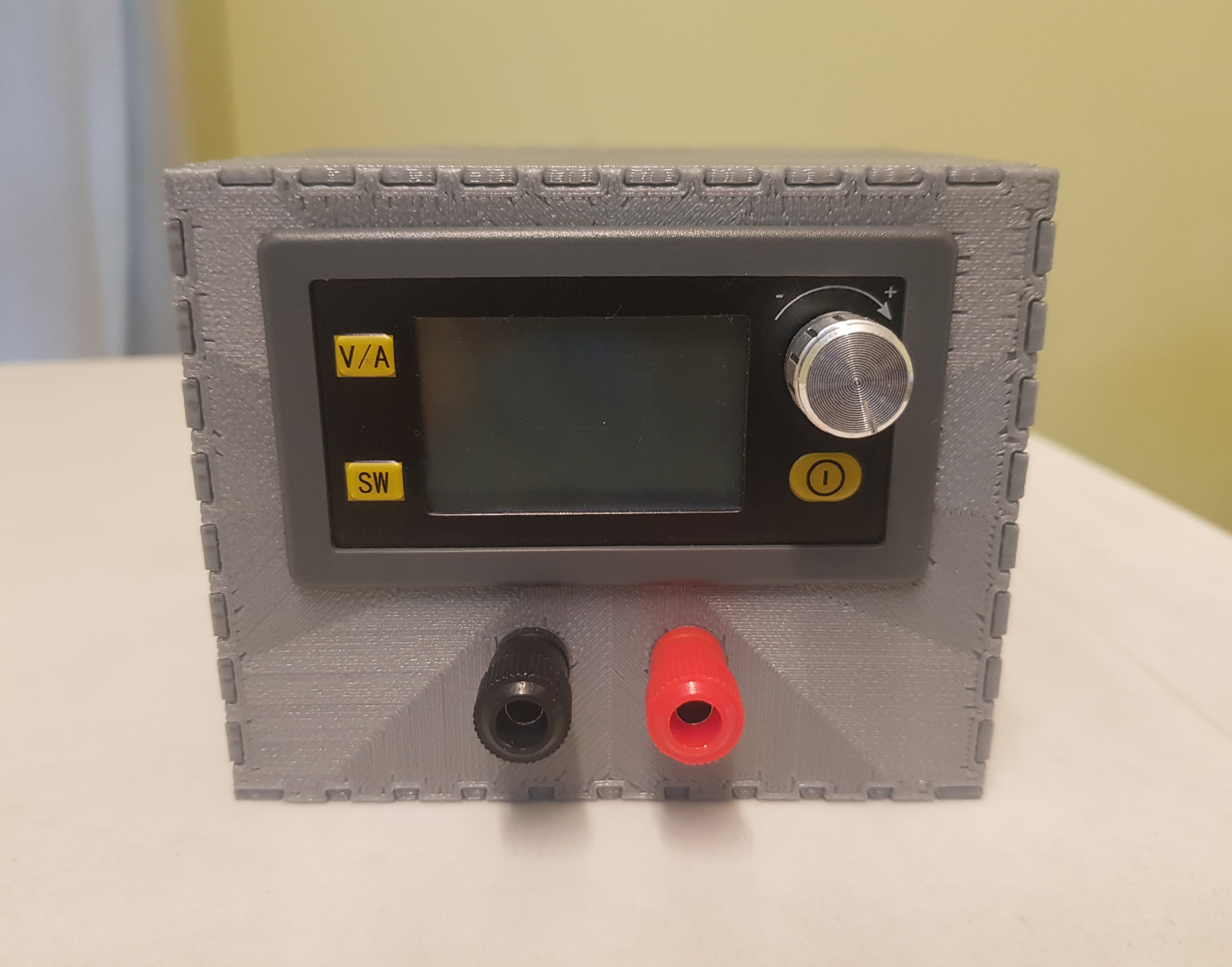

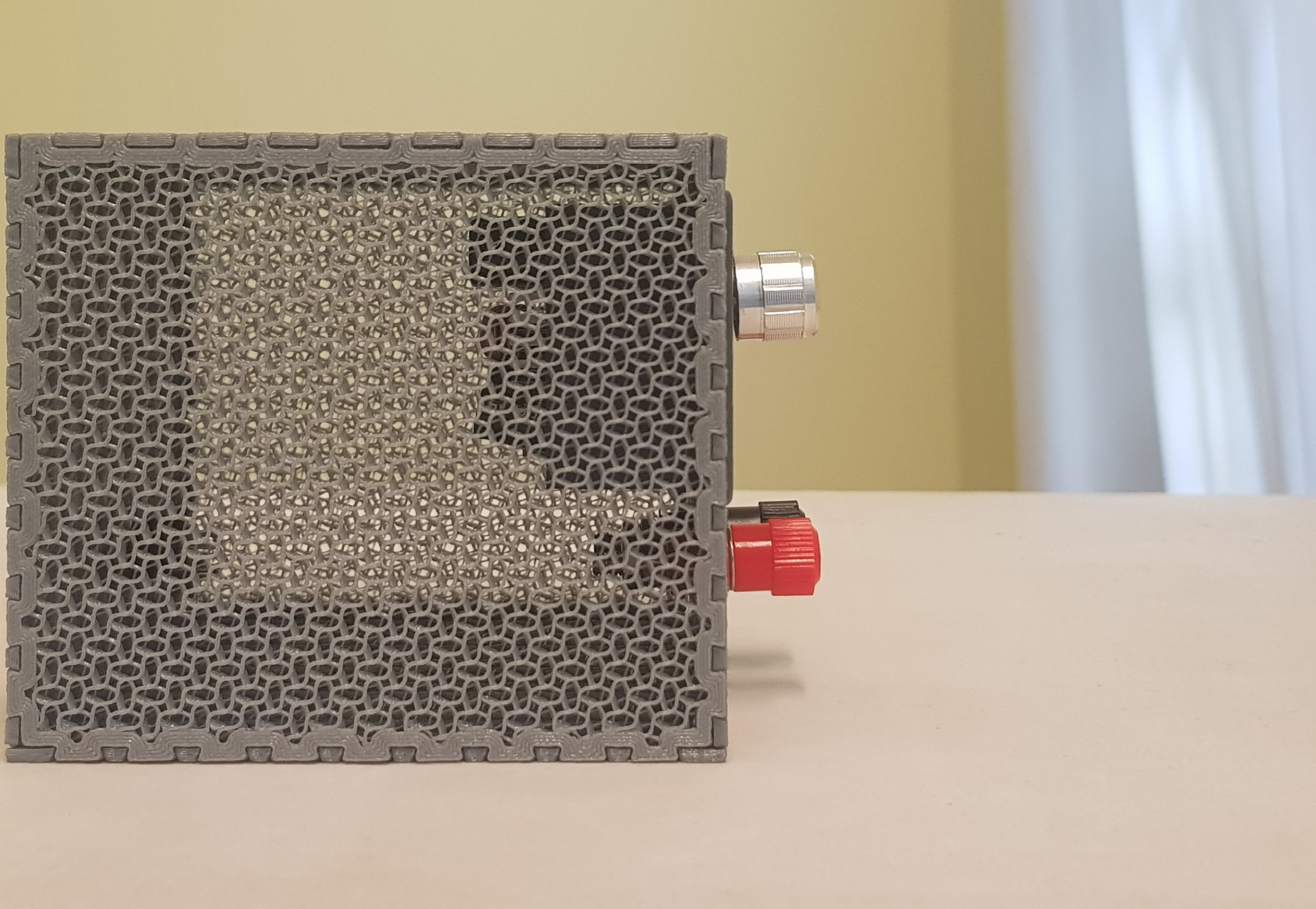

It is held together completely by the joint. These dovetail joint are known to be very strong reliable.

x7tYnC6c

The interface module which do everything is just the cheapest one I found locally. It called a buck boost module but that doesn't really narrow it down. Other than that it's just 2 binding posts and whatever supply you want. I used a barrel jack plug to reuse my old laptop charger.

That's the neat thing! If passive convection can't do the job, I just have to print a new top plate with fan mount.

Not everyone cup-of-tea, but build123d/cadquery is pretty good if you like programming. I used it to make some dovetails joint which would be annoying to do with gui cad.

This is only a prototype, you can see there are no wiring inside. The artifacts are because I print at 150m/s and 5k acceleration, on a bed slinger.

While these changes will eventually happen, as all of these companies are meant to make a profit from the start. The reason they're all happening now is because of the coming recession, or at least the believe that it will come.

Yes.